Extend the Lifespan of Your Industrial Hose Fittings with a Maintenance Plan

When it comes to industrial hose fittings, quality and fit matter. Instead of using off-the-rack solutions, you should invest in custom industrial hose fittings that are precisely designed for your equipment and intended application. When the length, material thickness, and size of your industrial hose fittings are optimized, they will perform better and last longer.

However, even if you have taken the extra steps to maximize product performance, you still need to create and adhere to a detailed maintenance plan. The maintenance plan for your industrial hose fittings should outline the following:

- How often you inspect your hoses

- How often you replace hoses

- What signs of wear warrant hose replacement

- Who is responsible for conducting hose inspections

Creating a maintenance plan will help your business run smoothly and safely.

Ensure Hoses and Fittings Are Inspected Properly

A visual inspection is the most practical way to ensure that your industrial hoses and fittings are in good working order. These visual inspections should occur on a regular basis, at least once per month. Hoses and fittings installed on high-pressure applications should be visually inspected more frequently, such as weekly.

Inspectors should be on the lookout for concerns such as:

- Cuts or cracks on hoses or fittings

- Charring

- Leaks

- Loose covers

If any of these issues are discovered, the hoses and fittings need to be replaced before the machinery is put back into service.

Ensure Auxiliary Components Are Inspected Properly

During inspections, auxiliary components should also be examined. Your staff should check for the presence of the following:

- Leaks

- Excess buildup of dirt or debris

- Worn-out guards or clamps

- Air entrapments

Depending on the type and severity of the deficiency, components will either need to be tightened/adjusted or replaced entirely. These issues must be resolved promptly to prevent machinery failure or workplace safety hazards.

Conduct Appropriate Testing

Conducting a visual inspection of hoses, fittings, and auxiliary equipment is a vital part of an effective maintenance plan. However, in addition to a visual inspection, your team must also conduct equipment testing to ensure that the machinery is operating efficiently.

During testing, inspectors should also verify that hoses and fittings are not subjected to excessive pressure. If equipment is operating beyond peak efficiency levels, the excess pressure can cause hose or fitting failure.

Prevent Catastrophic Failures

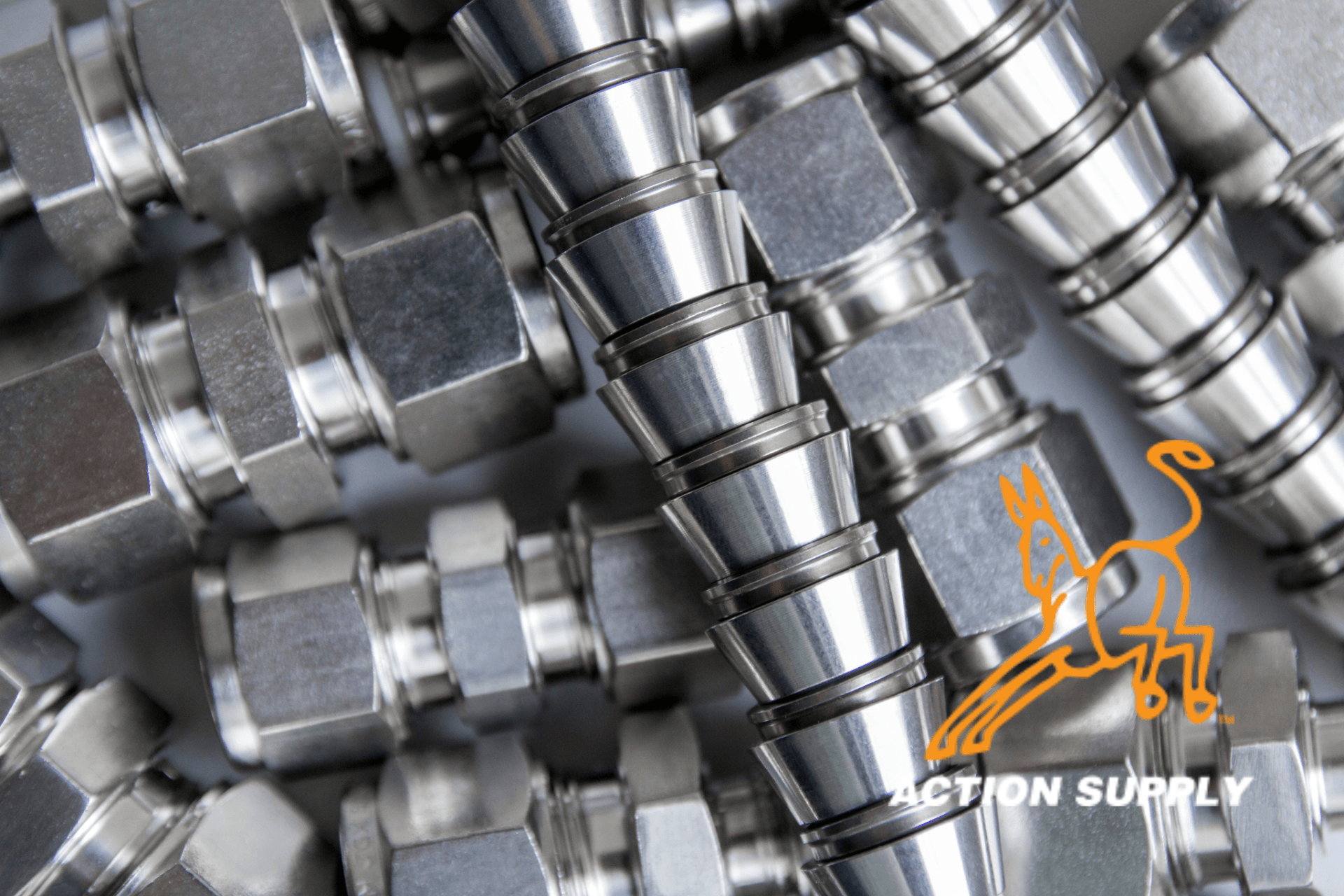

The core purpose of your maintenance plan is to identify issues with your industrial hose fittings, hoses, clamps, and other equipment before a catastrophic failure occurs. However, identifying deficiencies is only part of the equation. It is equally important that you replace damaged hoses and fittings with high-quality components, such as those provided by Action Supply.

As an industry leader, we can provide you with top-quality hydraulic fittings and industrial hoses. We also provide hose inventory management and on-site assembly services.

Action Supply is a reliable supplier to help you achieve your industrial hose maintenance goals. Contact us today to learn more about our suite of services and products.