How to Winterize Hydraulic Hoses of Construction Equipment

It's essential to prepare the hydraulic hoses of your construction equipment for the cold season, especially if any part of your equipment will be exposed to severe winter weather and temperatures. Otherwise, you risk mechanical issues and equipment failure that result in costly repairs and downtime. Here are some steps you can take to protect your hydraulic hoses from winter weather.

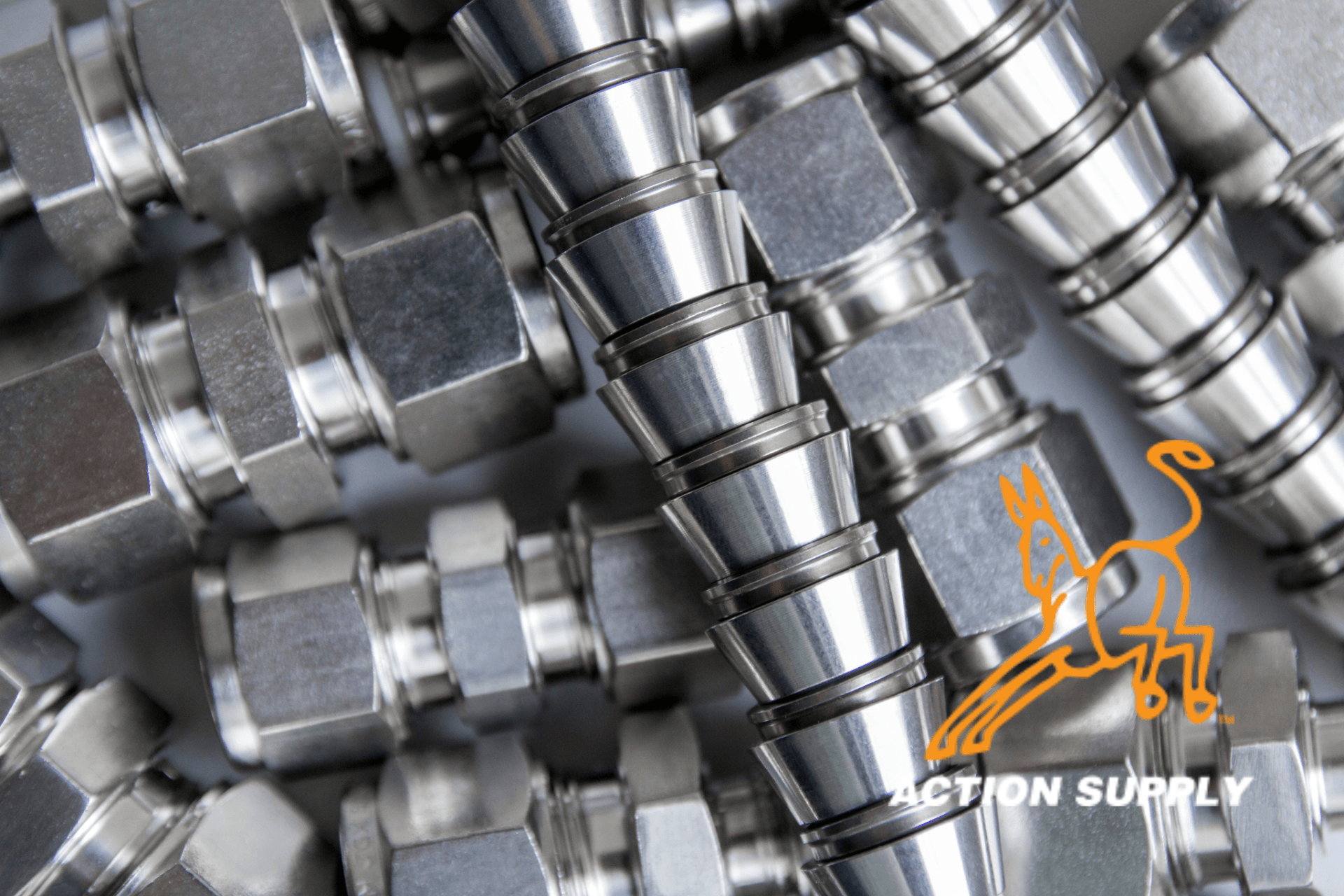

Inspect and Clean Hydraulic Hoses

Begin by thoroughly inspecting all hydraulic hoses to ensure they are in working order. Look for any signs of:

- Normal wear and tear

- Damage to the hoses, fittings, and fasteners

- Signs of incompatible fittings

- Leaks

- Kinks or too much torsion in the line

- Signs of abrasion from friction

- Inconsistent pressure or signs of blockages

- The hose specifications ensure that they can withstand the closest temperatures that they could possibly be exposed to.

Replace or repair damaged hoses and faulty parts. Clean both new and existing hoses and connections to remove dirt, debris, and contaminants.

Check Hydraulic Fluid and Lubricate Parts

Cold weather can affect hydraulic fluid's viscosity, so make sure the fluid in your construction equipment is suitable for the temperature and weather conditions they will be exposed to. Consult your equipment's manual or supplier for specific recommendations.

Proper lubrication is vital in cold weather to keep your construction equipment working smoothly. Lubricate all moving parts, such as joints, pistons, and cylinders, according to manufacturer instructions for winter weather. Replace any parts that may not be suitable for freezing temperatures, ice, and other environmental factors. These steps will prevent parts from freezing and seizing up in the cold.

Protect Exposed Hoses

Exposed hydraulic hoses are susceptible to freezing and damage in winter. Their porous surfaces can become brittle and crack as they are exposed to extreme or fluctuating temperatures. To prevent cracks and leaks:

- Use insulated wraps and sleeves to create a barrier between exposed pipes and winter weather.

- When feasible, use temporary shelters or outdoor heaters during unusual weather patterns to protect vulnerable areas.

- Make sure they are sheltered from heavy snow and ice deposits that could put extra strain on their fasteners and lower their fluid temperatures.

- Inspect any exposed and sleeved pipes after extreme weather storms.

- If possible, actively monitor fluid temperatures for signs the hydraulic hoses are compromised.

These protective measures will maintain the hoses' flexibility and prevent cracking.

Run and Shelter Equipment and Spare Parts

Letting equipment and hoses sit unused in freezing conditions risks frozen parts, ice buildup, blockages, and other issues. Store your spare parts and unused construction equipment in a dry, climate-controlled indoor space.

Extra care of resting equipment is necessary to prevent hydraulic fluid from becoming too thick and sluggish in cold temperatures. Start and run your equipment regularly, even if you do not plan to use it immediately. Before using equipment that sat unused in the cold, run it for about an hour to warm the parts and fluid before using.

Be Prepared for Emergencies

Despite your best efforts, emergencies can still happen in winter. Always have a cold-weather emergency kit on hand, including spare hydraulic hoses, hydraulic fluid, and necessary tools for quick repairs. Also, make sure you have a supplier who can provide expert advice and parts fast.

Let Action Supply Help You Winterize Your Hydraulic Construction Equipment

Action Supply’s representatives are committed to taking the stress off your shoulders. Our inventory management ensures you always have the part you need, and we will even assemble the hoses on-site for you.

Contact us today to make sure your hydraulic lines are fully winterized.