Identifying and Fixing Incompatible Fittings on Industrial Hoses

Industrial hoses play a critical role in various applications across multiple sectors, and their efficiency and safety are heavily dependent on their fittings. Proper hose fittings are not a small concern on your work site. Using incompatible fittings by choice or due to an error can pose significant safety risks like

- Spills and Environmental Hazards

- Damage to nearby Equipment

- Slips, chemical burns, poor air quality, and other workplace hazards

- Downtime and Operational Delays

Here are some ways to recognize incompatible fittings before they cause larger problems, and things to consider when choosing their replacements.

Recognizing the Signs of Incompatible Fittings

Incompatible industrial hose fittings can lead to several noticeable problems. Being aware of the signs can help prevent or mitigate potential issues before they escalate into larger problems.

- Leakages. One of the most apparent signs of an incompatible fitting is leakage around the fitting site. When the hose and fitting don't match, there might be gaps that allow the transported material to escape.

- Loose Connections. If the fittings are not designed for a particular hose, they might not secure properly. This can result in the fitting coming off under pressure, leading to loss of material and workplace hazards.

- Visible Wear and Tear. Incompatible fittings can corrode from exposure to the fluids or cause accelerated wear and tear at the connection points. Over time, this can lead to cracks, splits, or deformities in the hose.

- Inconsistent Flow Rate. Loose connections can cause the material to slow at a sub-optimal rate, cause random surges, or slow and block the flow altogether. If you find the flow rate is fluctuating without explanation, it may be time to check the fittings for issues.

How to Choose the Right Fittings for Specific Hoses

For industrial hoses to function properly, the correct fittings are essential. Here are some essential factors to consider:

- Hose Specifications. Make sure the fitting matches the hose’s inner and outer diameter and that it has an adequate pressure rating to meet operational demands.

- Application Needs. Gases may require different fittings from fluid materials. In addition, the operating temperature range, the temperature of the materials, and the route the materials will take all determine the best fitting type and function.

- Manufacturer's Guidelines. Manufacturers provide tested and proven fitting recommendations. Using these guidelines ensures an optimized fit and can extend the hose's operational lifespan.

- Material. Some materials corrode or create chemical reactions when exposed to specific materials within the hoses. This can lead to breaks, leaks, or contamination of the transported material. Make sure you use fittings made to safely transport the intended fluid or gas to avoid these issues.

- Connection Type. Crimps are designed to offer a permanent bond between the hose and fitting, while push-on connections offer easy assembly for low-pressure applications. Flange assemblies are made for larger hoses and high-pressure situations. Barbed and threaded couplings also offer their unique advantages and disadvantages. Choosing the right type of fitting is critical for the effectiveness and longevity of your system.

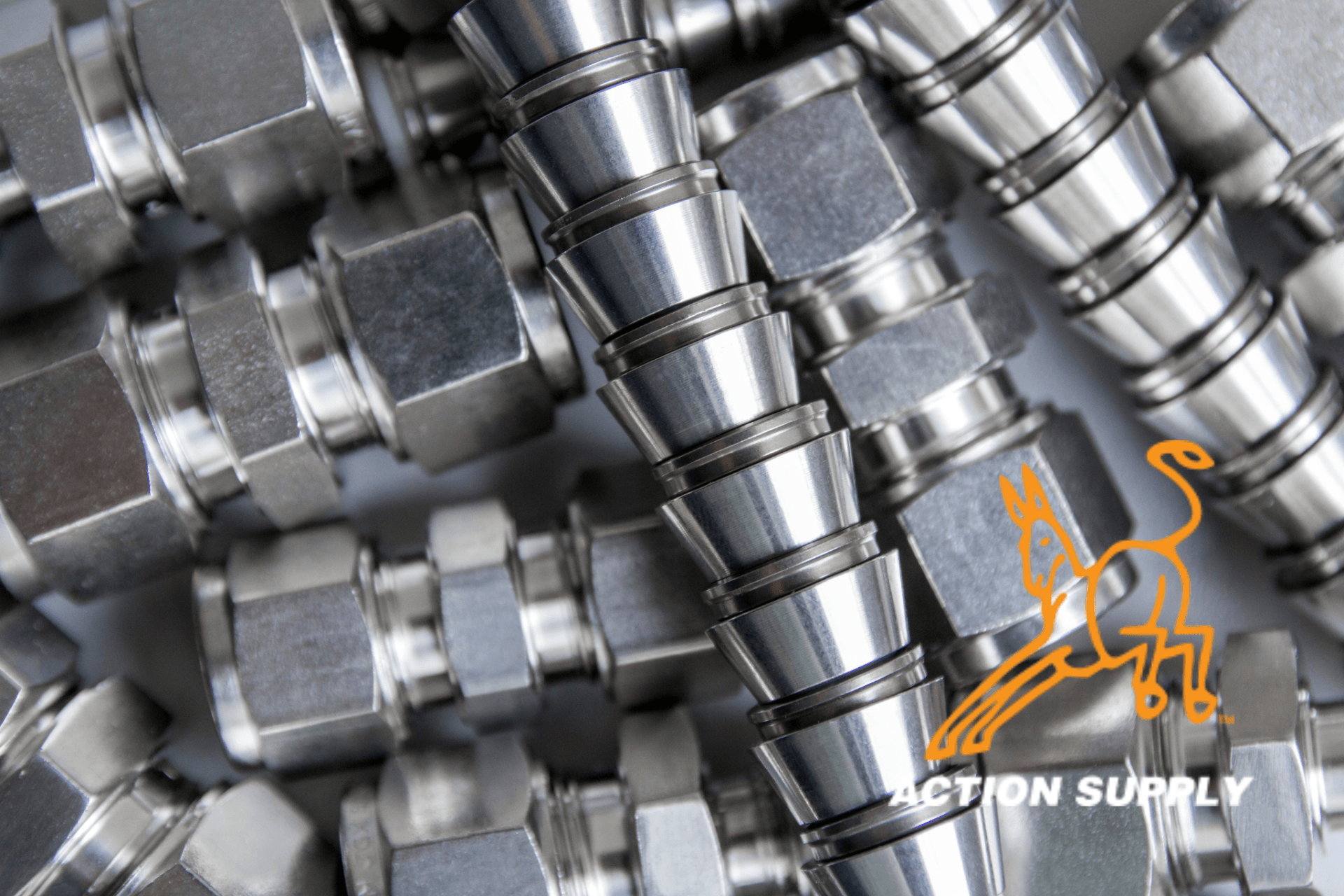

Action Supply Ensures You Always Have the Right Fittings For Your Industrial Hose Line

Our account representatives are committed to taking the stress off your shoulders. We make sure the exact industrial supplies you need are always available. They will be stocked, organized, and easily accessible whenever you need them. Contact us today to ensure you always have the hoses and fittings you need.