In A Hurry For A Product? Try Hot Shot Trucking.

As supply chain disruptions caused by the pandemic continue to ease, businesses are picking up production. That means the need for adequate and timely shipping and delivery of products is in high demand. For many jobs, lighter-than-truckload (LTL) shipments are an efficient way of getting goods to their final destination.

LTL truckers generally will have two or more individual loads on one large truck, using a hub-and-spoke method to relay products across the state or around the country. However, as the demand for better supply line efficiency has grown, so has the demand for more and faster shipping options.

Today, many companies are willing to pay a slight premium for a more customized solution. ‘Hot Shot Trucking’ – using smaller vehicles (pick-up trucks, SUVs or Sprinter vans, for example) to take a vital shipment directly to the buyer – has become a larger part of the LTL industry.

Hot Shot Truckers are usually owner-operators who bid for jobs in an online portal. While it is an efficient way for those needing transport for products and those able to provide that transport to find each other, there are some key factors that need to be determined before finalizing a job.

Pre-Planning the Route

Proper planning of the route is a crucial step. Operators need to check for road closures, bad weather and chronic traffic disruptions along their proposed route. If it looks like there might be a problem, they should determine alternate routes ahead of the trip to make sure the delivery gets to its destination in the necessary timeframe.

Proper Vehicle Maintenance

Since even a minor breakdown can cause problems with a scheduled delivery, it greatly benefits every hot shot trucking operator to take excellent and consistent care of their vehicles.

A Fair and Accurate Shipping Estimate

Every company needs the ability to accurately plan budgets and timelines, so securing an on-target, in-writing estimate for your hot shot delivery is important. Hot shot trucking jobs are usually quoted as a flat rate, depending on factors like the size of the load, what type of vehicle will be necessary to carry it, and the mileage required to get from the original to the planned destination.

While standard LTL shipping is still usually a more economic way of moving product, hot shot trucking operators are a great option for delivering products in a customized-to-you timeframe.

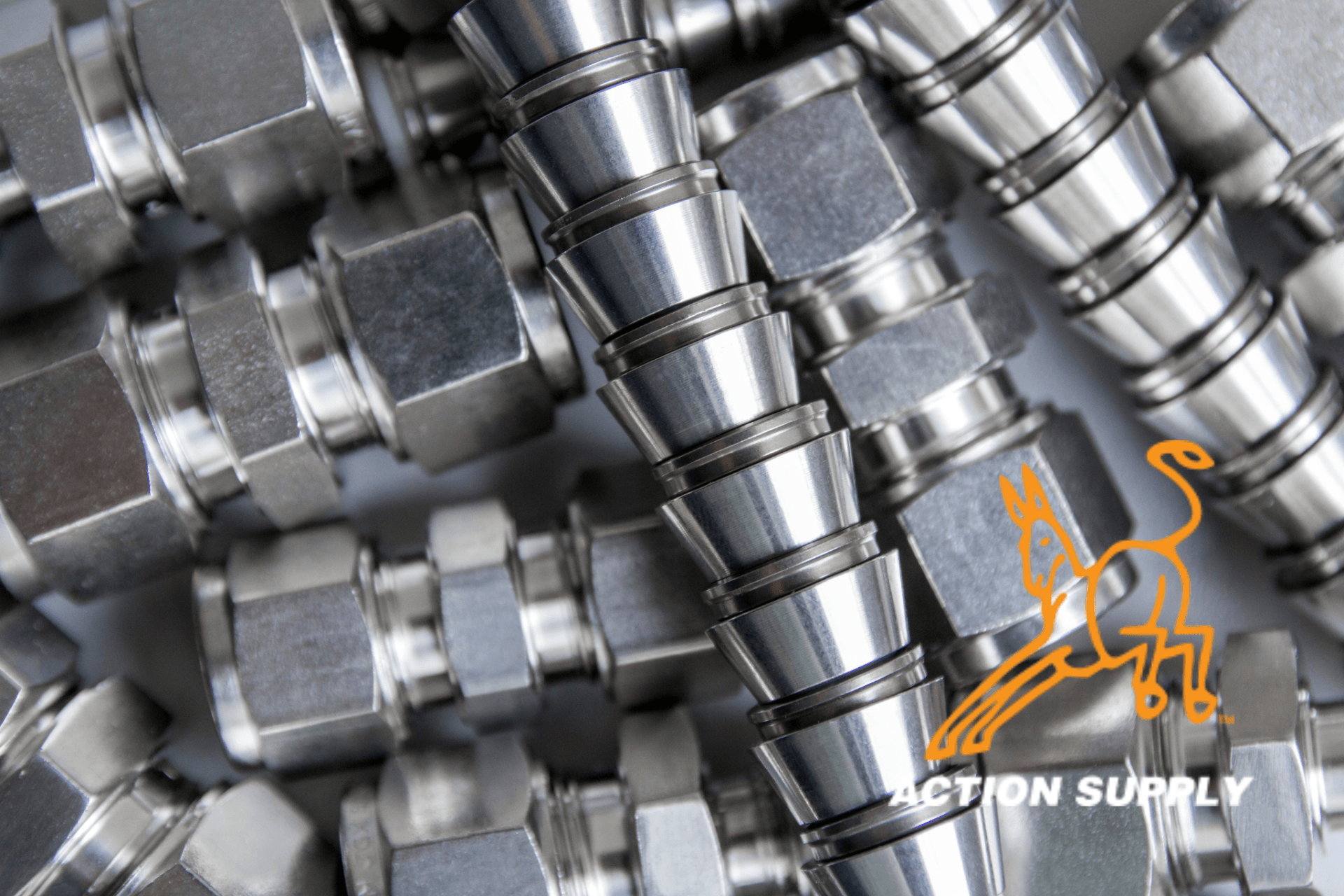

Need Industrial Hoses or Hydraulic Fitting Solutions Fast?

In addition to our timely and trusted standard delivery methods, Action Supply -- a leader in providing the highest quality industrial hoses and hydraulic fitting solutions – offers hot shot trucking to get key products to our customers quickly and safely. All of our products are designed with dependable, industrial-strength materials and are crafted to withstand the most rigorous industrial conditions.

In this industry, the need for the right product at the right time is often essential to larger projects moving forward. We have a well-developed hot shot trucking service that meets all the criteria discussed above. You can rely on Action Supply to get you the right product – fast! Contact us today for a quote.