The 7 Key Factors to Select the Right Industrial Hose

Selecting the right industrial hose is crucial for the safe and efficient operation of many industrial processes. There are several key factors to consider when choosing an industrial hose. Here are seven that cannot be compromised if you want to optimize their use.

1. Size and Length

Using the wrong size or length of the hose can lead to pressure drop, reduced flow rates, or excessive stress on the hose.

- Inner Diameter (ID). Proper ID ensures efficient fluid transfer, prevents clogging, and enhances hose performance for specific applications. This promotes safety and functionality.

- Outer Diameter (OD). OD measures its entire cross-sectional span, including the inner tube, reinforcement, and outer cover. The difference between the ID and OD determines how thick the hose is.

- Length. The length determines how far the hose can extend, allowing it to reach specific areas or provide adequate coverage. Longer hoses offer greater flexibility and maneuverability, enabling easier handling and positioning in various applications. However, if a hose is too long, it can result in pressure drops, friction damage, tripping hazards, and other issues.

2. Temperature

Selecting a hose that maintains its integrity at the intended temperature is crucial for preventing accidents, leaks, or burst failures. This includes the ambient temperature of the environment.

- Fluid Temperature. Fluid temperature can affect the viscosity and flow properties of the material it is transporting. Hoses must be capable of accommodating the specific fluid characteristics at the intended temperature.

- Ambient Temperature. Exposure to extreme temperatures, UV, and other environmental factors affects material performance, flexibility, and pressure ratings.

Hoses that are not suitable for the ambient temperature may become more prone to failure, leaks, or ruptures, compromising safety and system performance.

3. Application Compatibility

Make sure the hose is in compliance with your industry’s local and federal regulations for the job. This includes environmental safety and industry standards.

4. Medium

Different hoses are designed to handle various substances, temperatures, pressures, and environments. Ensure that the hose is compatible with the material it will be transporting. This includes the mediums that will be used to clean industrial hoses to avoid chemical reactions and degradation.

5. Pressure Rating

Determine the maximum operating pressure required before making your purchase. While industrial hoses as all made to withstand considerable pressure, some will require higher pressure ratings than others.

The pressure rating is influenced by the hose's material and construction, so selecting the right hose ensures compatibility with the conveyed fluid and environmental conditions. It also affects other factors like the hose’s flexibility, bend radius, costs, and maintenance.

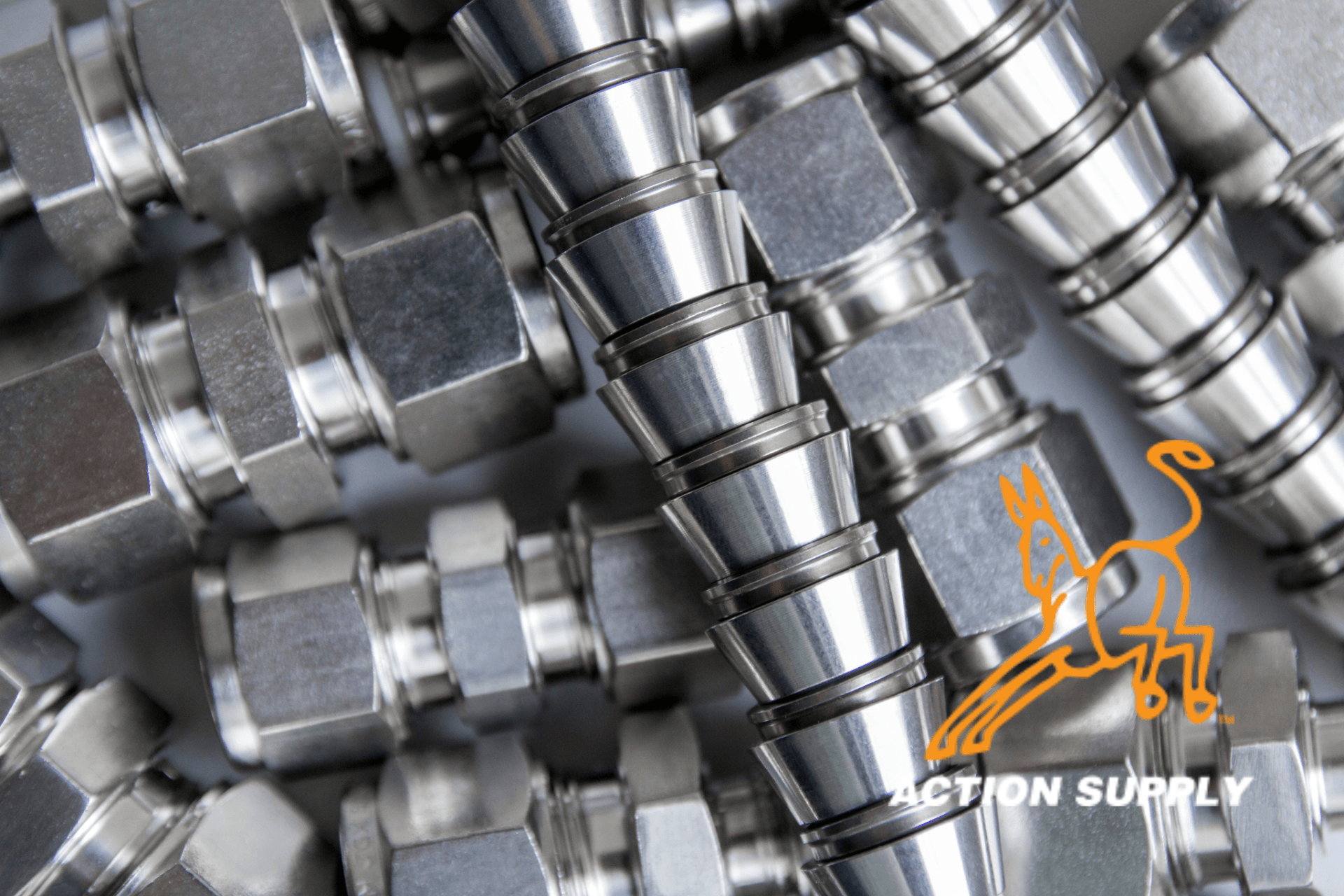

6. Ends

The type of ends or fittings on an industrial hose is vital for proper installation and functionality. Selecting the right hose ends that match the hose's inner diameter and construction ensures a proper fit and optimal performance. They should also be made from materials compatible with the transported fluid to prevent chemical reactions and contamination.

Different systems require specific end connections based on the system requirements. These could include but are not limited to camlock fittings, flanges, quick-connects, or threaded fittings.

7. Supplier Reputation and Support

Choose a reputable supplier that offers technical support and assistance in selecting the right hose for your specific application. Here are just a few reasons the supplier is just as important as the hose itself:

- A reputable supplier is more likely to provide high-quality hoses that meet industry standards, reducing the risk of product defects or failures.

- Reputable suppliers ensure their hoses meet relevant certifications and regulatory requirements, ensuring safe and compliant use.

Reliable suppliers offer technical assistance with hose selection, installation, and troubleshooting. They also provide excellent after-sales support like assisting with warranty claims, replacements, or maintenance.

Action Supply Offers Over 40-Years of Industrial Hose Expertise

We are committed to providing you with the highest quality customer care and have done so for over 40 years. Our inventory experts will work hard, earn your trust, and help you get the job done right. Contact us today to discuss the perfect industrial hoses for your system.