Top Fleet Maintenance Tips for 2024: Keeping Your Vehicles in Prime Condition

As we look ahead to 2024, it's crucial to adopt proactive strategies that ensure your fleet remains in optimal condition. This blog post will provide you with a comprehensive guide to fleet maintenance tips for the upcoming year, helping you reduce costs, improve safety, and enhance overall efficiency.

Research Upcoming Changes to Regulations

2024 is seeing a lot of changes to how you manage your business vehicles. A few things you should brush up on for 2024 include:

- The Corporate Transparency Act

- State and Federal Commercial Driver’s Licence and Driving Law Changes to keep your team in compliance. Make sure to review every state you do business in.

- Changes to tax deductions for purchasing fleet vehicles

Update Technology

Update and utilize fleet management software to streamline operations. These systems can help you track vehicle maintenance schedules, monitor driver behavior, and analyze data to make informed decisions.

Equipping your fleet with advanced sensors and telematics systems will help you monitor vehicle health in real time. These systems can predict potential issues before they lead to breakdowns, saving you both time and money.

Prioritize Regular Inspections

Regular vehicle inspections are the backbone of a well-maintained fleet. Ensure that your maintenance team conducts thorough inspections at scheduled intervals. This proactive approach can identify minor issues early, preventing them from escalating into costly repairs.

Optimize Fuel Efficiency

Implement eco-driving techniques and monitor fuel consumption closely. Regularly servicing and tuning your vehicles can improve fuel efficiency and reduce your carbon footprint.

Monitor Tire Health

Well-maintained tires not only improve fuel efficiency but also reduce the risk of accidents. Check tire pressure and tread depth to ensure optimal performance and safety. Look for signs of alignment issues that shorten the life of your tires as well.

Inspect All Safety Equipment

Inspect all safety features like airbags, headlights, seatbelts, and electronic stability control systems.Make sure any emergency supplies like road flares, cables, and hazard cones are in top shape. Don't forget to ensure each driver’s PPE gear is in good condition as well. Ensure that your drivers are well-trained in safety protocols and encourage a safety-conscious culture within your organization.

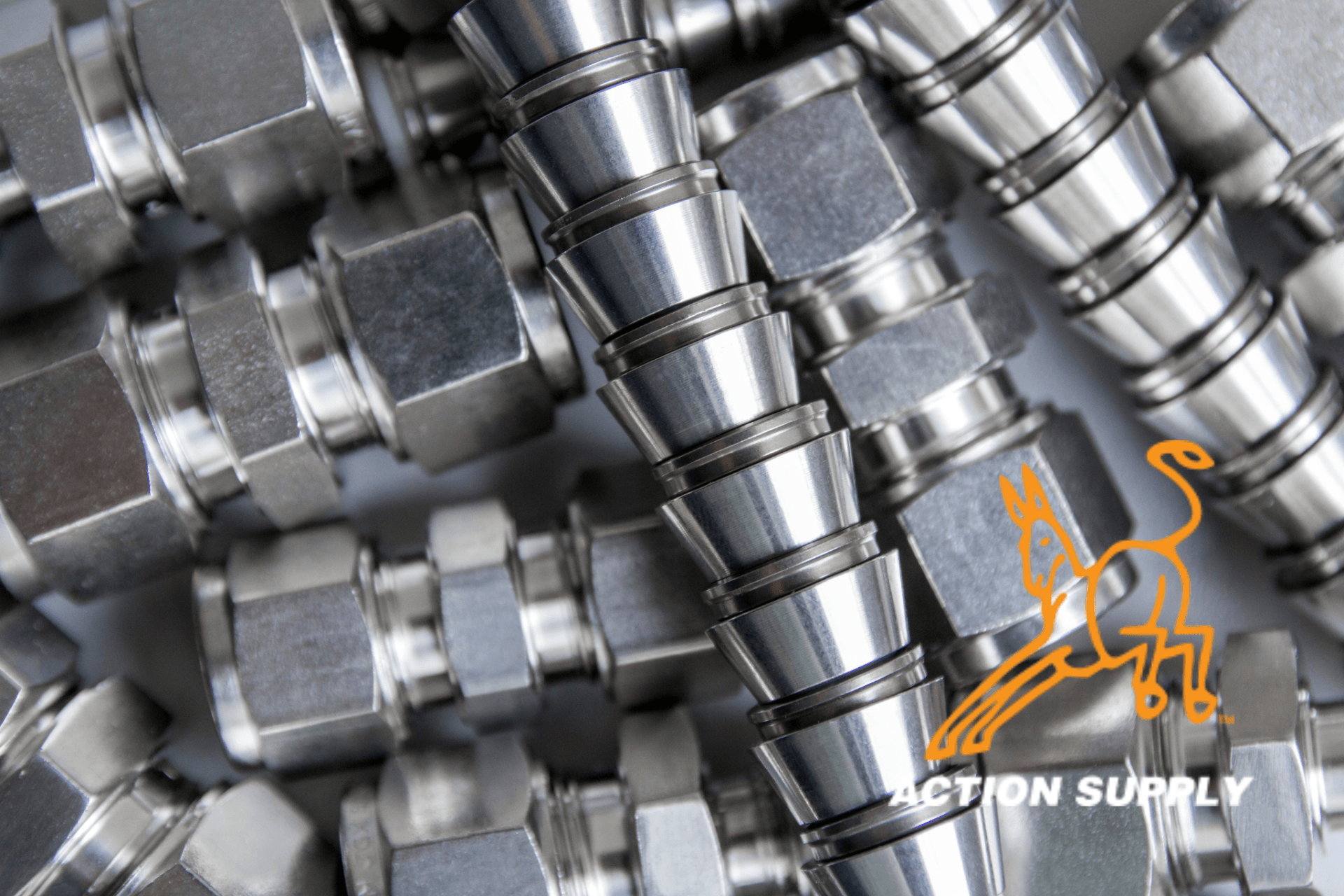

Let Action Supply Help You Keep Your Fleet Supplies in Top Shape

We offer fleet management solutions that are industry-tested to meet the highest performance standards. Whether you're looking for radiator hoses, backup alarms, gauges, or air brake replacements, we have solutions you can trust. Contact us today to ensure your fleet is well-maintained for 2024.