Why Do Hydraulic Hoses Fail?

Heavy-duty motorized equipment is built to be tough. But even the toughest materials can lose their strength with prolonged use. So with all the wear and tear your equipment goes through, how can you prevent your hydraulic hoses from failing? First, you must understand what’s causing the issue.

Seven Reasons Why Hydraulic Hoses Fail

Abrasion

The number one cause of hydraulic hose failure is abrasion. Because these hoses expand and retract during use, they’re constantly moving and are therefore more prone to rubbing. The more the hose rubs, the weaker the materials become. Leaks occur when the outer hose cover is entirely worn away by abrasion, exposing the steel wire reinforcements inside. Fortunately, it’s relatively simple to prevent abrasion on your hydraulic hose. Many manufacturers add plasticizers to the hose cover textile to make it hardier. You can also easily cover any problem areas on your hose with a nylon sleeve or plastic guard.

Routing Issues

Poor routing can expose parts of your hose to increased abrasion. When laying down your hydraulic hose, try to avoid routing it through high-friction or high-temperature areas and pivot points. Be aware of the hose’s minimum bend radius, as excessive bending can cause future issues and eventual hose failure. If you think it will be moving a lot, try using a swivel at the end of it.

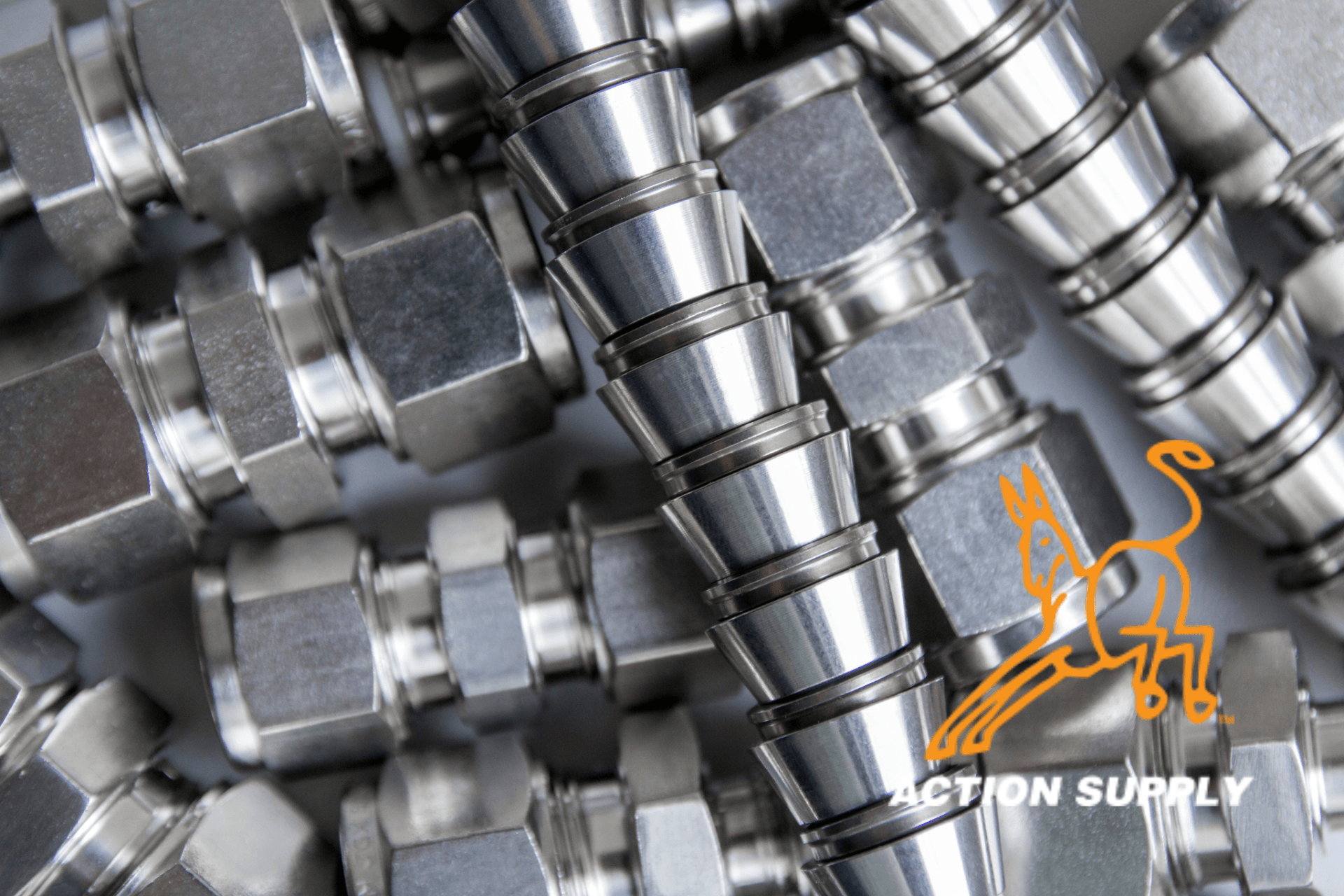

Improper Fittings

The fitting, where the hose meets the crimp seal, can also be a frequent source of failure. If the hose bends too closely to the fitting, whether due to the weight of the hose or poorly planned routing, it won’t work correctly. You can fix this with a bend restrictor, a simple plastic product that helps to support the hose around the fitting.

Heat Exposure

High temperatures are not a hydraulic hose’s friend, and when they’re exposed to high heat, they can start to stiffen and lose flexibility. Heat aging, or prolonged exposure to high temps, can cause hoses to splinter from the inside out. If you bend a hose and hear a crack, and it doesn’t bounce back to its usual shape, your hose is experiencing heat aging. Route carefully (see above), and consider buying a heat sleeve for your hose to prevent this.

Installation

Good hose maintenance starts at installation. When they’re installed, the hoses must be cut to size, then thoroughly flushed to clean out any debris that may be left inside. Then the fittings should be crimped, and finally, the hose should be clamped. If you don’t install it correctly, the hose won’t work as it should.

Fluid Compatibility

Not all fluid is compatible with all hoses. Even a high-quality hydraulic hose can start to erode if it’s used with the wrong types of fluid - the fluid can disintegrate the insides of the hose, which slowly start to swell. If a leak occurs, you may have some serious particulate contamination in your hydraulic system.

Erosion

It’s not just incompatible fluid that can damage your hoses. High-velocity fluids rushing through your hose can also start to wear away at its insides. It’s important to choose a hose that is suited to the expected velocity of the fluid inside.

It’s essential to prevent hydraulic leaks, but if you’re past the point of prevention, there’s help for you. At Action Supply, we are pleased to offer

in-house hose repair services to keep your equipment working as hard as you do!