Equipment that Performs Under Pressure

February 3, 2020

Results On Your Terms

Industrial projects require the highest attention to detail and equipment that can withstand the toughest conditions. Don’t settle for industrial equipment

that works well one day and the next day it breaks down. Your projects deserve the best equipment that won’t let you down when you need it the most. If you are looking for different results from what you are currently experiencing we can help.

Performance In Tough Conditions

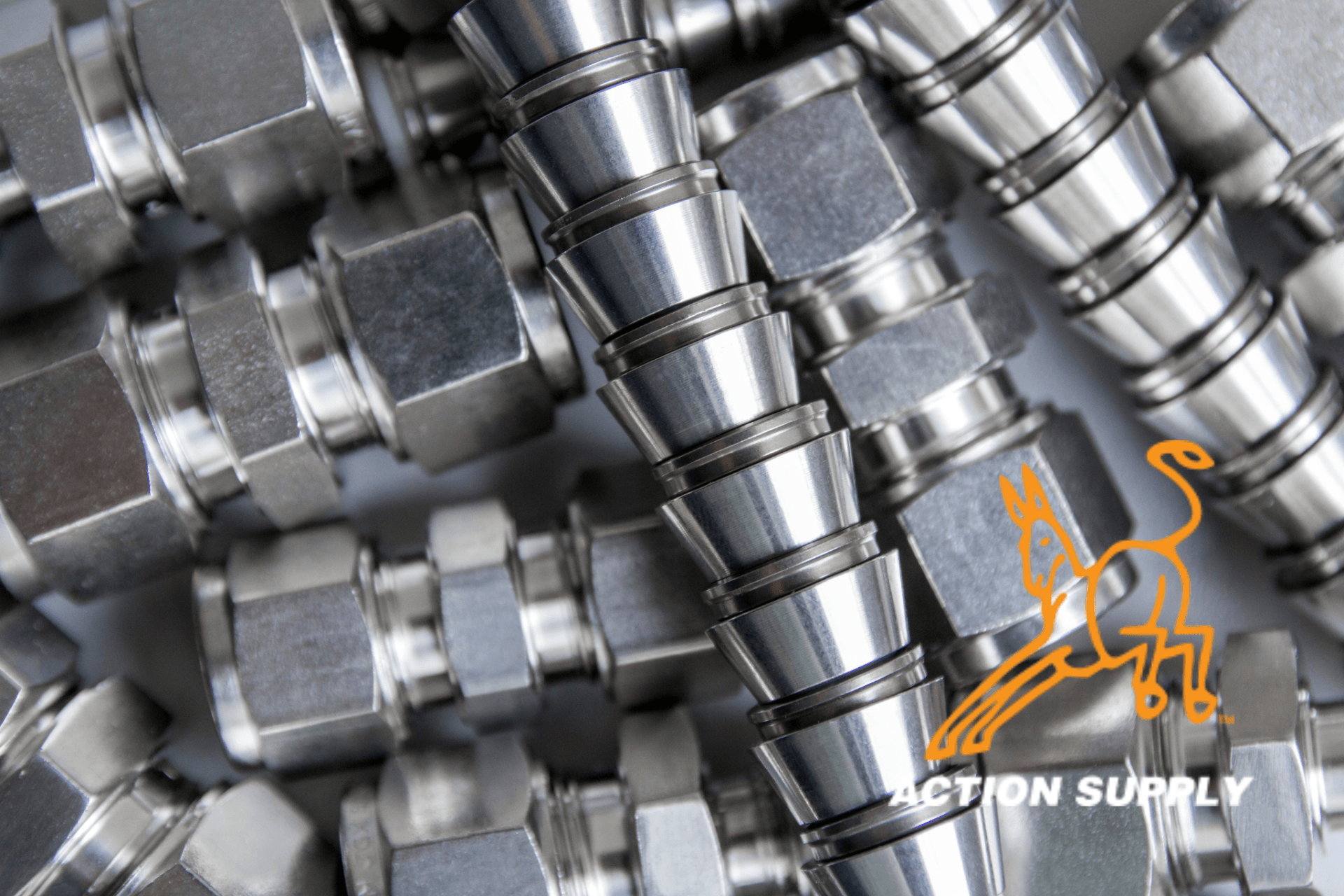

Get consistent results on your next project with our proven equipment solutions and inventory management. From us, you can expect the best performance results to complete projects efficiently, even under pressure. Our hydraulic hose solutions are designed for longevity, which means even after repeated use you can expect consistent performance. This is possible due to the attention to detail in the manufacturing stages and our reinforcement technology.

Custom Solutions For Your Industrial Goals

If you are experiencing delays with your industrial projects we have proven solutions to help you get them completed on time. Our goal is to help you maximize the most out of your time. Instead of repairing the tools that are supposed to make your job easier, we’ll make sure you have the latest and greatest tools available. In fact, for our industrial hoses we can create custom colors to match the color of your brand. Your goals are unique so we listen and then take action to meet or exceed your expectations.

To learn more about how we can help with your next project get connected

with us today!

The start of a new year is more than a calendar reset, it’s an opportunity to strengthen the systems that keep your business running efficiently. For industrial, commercial, and maintenance-driven operations, having the right supplies in place at the right time can mean the difference between staying productive or falling behind. Building a smarter supply strategy early in the year helps businesses control costs, reduce downtime, and remain competitive in an increasingly unpredictable supply environment. Here’s how to evaluate your needs, forecast usage, and put reliable systems in place for the year ahead. Why Strategic Supply Planning Matters Reactive purchasing often leads to higher costs, rushed decisions, and inconsistent inventory levels. Without a clear supply plan, businesses risk overordering, stockouts, and delays that impact operations and customer commitments. Strategic supply planning allows organizations to: Improve operational efficiency Reduce emergency purchases and downtime Stabilize pricing through better forecasting Build stronger supplier relationships When supply strategy is aligned with operational goals, purchasing becomes a competitive advantage, not just a necessity. Step 1: Evaluate Your Current Supply Usage The foundation of any effective supply strategy is understanding what you actually use. Reviewing historical purchasing data provides valuable insight into patterns, seasonality, and inefficiencies. Key questions to ask: Which products are used consistently throughout the year? Where do usage spikes or slowdowns occur? Which items frequently require rush orders or last-minute replenishment? Identifying high-use and critical items helps prioritize where planning and standardization will have the greatest impact. Step 2: Forecast Demand with Operational Input Accurate forecasting requires collaboration across departments. Operations, maintenance, and procurement teams all play a role in anticipating demand. Consider factors such as: Planned maintenance schedules Production volume expectations Seasonal workload fluctuations Equipment upgrades or expansions By incorporating operational insight into forecasting, businesses can better align inventory levels with real-world needs, reducing both excess stock and shortages. Step 3: Standardize Products and Vendors Standardization simplifies purchasing, improves consistency, and often reduces costs. Evaluating opportunities to standardize frequently used supplies—such as safety products, fasteners, tools, or consumables—can streamline procurement and inventory management. Working with a trusted supplier also provides access to product expertise, availability insights, and alternative solutions when supply challenges arise. Step 4: Set Systems in Place Early Establishing purchasing systems early in the year creates stability throughout the months ahead. This may include setting reorder points, implementing blanket orders, or coordinating scheduled deliveries for high-use items. Proactive systems reduce the need for emergency purchases and allow teams to focus on operations rather than constant supply management. Step 5: Build a Supply Partner, Not Just a Vendor A strong supply strategy goes beyond transactions. Partnering with a knowledgeable supplier adds value through product recommendations, inventory support, and responsiveness when challenges arise. The right supply partner understands your business, anticipates needs, and helps you adapt as conditions change throughout the year. How Action Supply Supports Smarter Supply Planning Action Supply works with businesses to develop supply strategies that support efficiency, reliability, and long-term success. By helping customers evaluate usage, identify opportunities for standardization, and implement dependable supply systems, Action Supply helps operations stay prepared, not reactive. Whether planning for routine maintenance, large-scale projects, or day-to-day operations, Action Supply provides the products and support businesses need to stay competitive all year. FAQs Why is supply planning important at the start of the year? Early planning helps businesses forecast demand, stabilize costs, and reduce disruptions caused by shortages or emergency purchases. How can businesses improve inventory efficiency? Evaluating usage data, forecasting demand, standardizing products, and working with a reliable supplier are key steps toward more efficient inventory management. What should a supply strategy include? A strong supply strategy includes usage evaluation, demand forecasting, product standardization, purchasing systems, and a trusted supply partner.